The Cornerstones

SAMPLE INJECTION CONTROLLED DISPERSION REPRODUCIBLE TIMING

1.2.5.

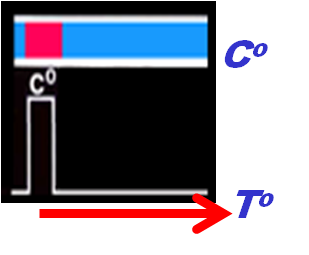

Sample injection provides the initial square input that serves as a starting point for the initial concentration (C°) and startup time.

SAMPLE

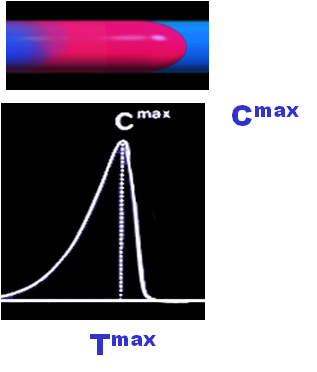

Controlled dispersion takes place as the sample zone moves downstream through the manifold. This process forms a well-defined concentration gradient that can be viewed as a continuum of elements of fluid with different concentrations, where the highest (Cmax) corresponds to the peak maximum. Since it is easy to locate the peak maximum, most FI methods use this element of fluid as a readout.

To optimize a given assay, it is useful to know to which extent a sample has been diluted in the FI system and how much time was available for the chemical reactions to proceed. For this purpose, the dispersion coefficient has been defined as:

D= C°/Cmax

allowing the degree of sample dilution to be estimated.

The time interval, Tmax is the time elapsed from the moment of injection T° to the moment of peak maximum Tmax. Reproducible timing of the sample travel from injection to detection yields a repeatable value of Tmax.

DISPERSED SAMPLE ZONE